Find the Right Cable Insulation for Performance, Protection, and Longevity

Choosing the correct insulation for your cable isn’t just about picking a material—it’s about optimizing performance, safety, and longevity. Different insulation types suit various environments and applications, and understanding the properties of each helps you make informed decisions.

Here’s a guide to some of the most commonly used insulation types and where they shine.

PVC (Polyvinyl Chloride)

Strengths:

- Flame resistance

- UV protection

- Flexibility

Best Applications:

-

Common applications:

-

Appliances

-

Medical devices

-

Outdoor environments

-

-

Key benefits of PVC insulation:

-

Versatile and cost-effective

-

Flame resistant

-

Durable against UV exposure

-

Suitable for moderate environmental demands

-

Resists chemical exposure, making it ideal for easy sterilization in medical devices

-

-

Example use case:

-

Medical devices that require flexible, sterilizable cabling often use PVC insulation.

-

-

See also:

Polyethylene (PE)

Strengths:

- Moisture Resistance

- Temperature Stability

- Excellent Dielectric Properties

Best Applications:

-

PUR insulation is built for rugged, demanding environments

-

Commonly used in:

-

Marine applications

-

Automation systems

-

Industrial and factory settings

-

-

Withstands consistent wear and tear

-

Highly resistant to:

-

Abrasion

-

Chemical exposure

-

-

Ideal for dynamic environments where cables are frequently moved

-

Delivers long-lasting, reliable performance under stress

Polyurethane (PUR)

Strengths:

- Abrasion Resistance

- Chemical Resilience

- Flexibility

Best Applications:

-

Tough and rugged, PUR insulation is designed for demanding industrial environments

-

Commonly used in:

-

Marine settings

-

Automation equipment

-

Factories and manufacturing floors

-

-

Built to withstand frequent movement and mechanical stress

-

Excellent resistance to:

-

Abrasion

-

Chemical exposure

-

-

A reliable choice for long-lasting performance in harsh conditions

Chlorinated Polyethylene (CPE)

Strengths:

- Oil Resistance

- Flame Retardance

- UV Stability

Best Applications:

-

CPE insulation is made for tough, high-demand environments

-

Commonly used in:

-

Power plants

-

Construction sites

-

Heavy industrial settings

-

-

Withstands exposure to:

-

Oils

-

Flames

-

UV radiation

-

-

Performs well in high temperatures and harsh conditions

-

Ideal for power cables that need to resist chemical and mechanical stress

Nylon

Strengths:

- Abrasion Resistance

- Flexibility

- Protective Layering

Best Applications:

-

Nylon is often layered over other insulation materials to boost durability

-

Commonly used in:

-

Automotive wiring

-

Applications with high mechanical stress

-

-

Enhances abrasion resistance in environments with frequent movement or friction

-

Protects the underlying insulation for extended cable life

-

Ideal for demanding conditions where long-term performance is critical

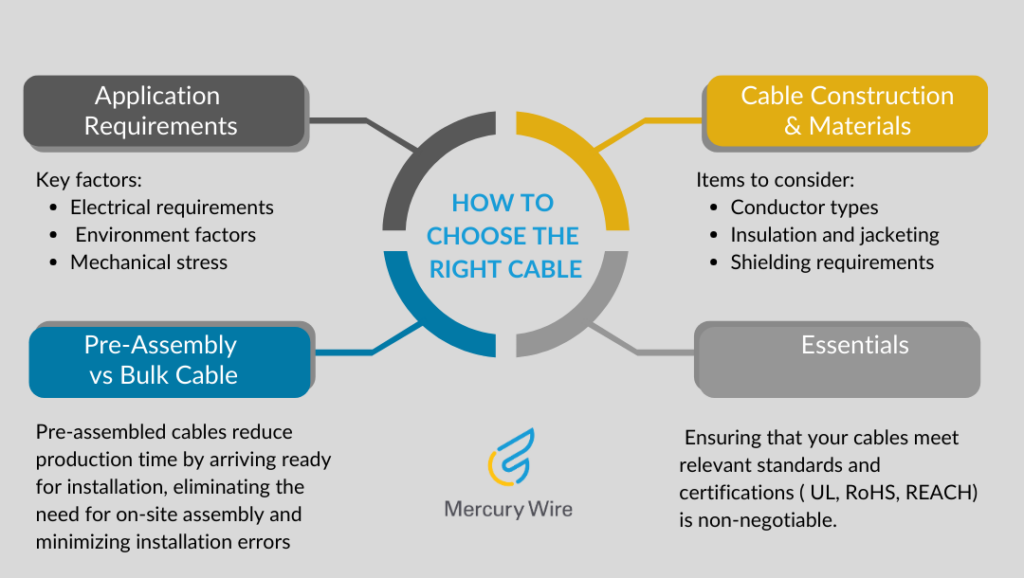

Key Considerations for Choosing Insulation

When selecting insulation, consider the environmental conditions, flexibility needs, safety standards, and lifespan required for your application. Each insulation material offers unique advantages, and balancing these against your needs will lead to the best solution. Mercury Wire offers expert insights into creating custom cable solutions that align with specific industry requirements, so don’t hesitate to reach out for guidance on selecting the best insulation for your cables.

For more detailed insights, visit Mercury Wire’s jacketing and insulation insulation guide. Need more information, why not reach out to one of our specialists who can provide you with guidance based on your specific needs.

See how we helped businesses like yours. Explore Our Case Studies